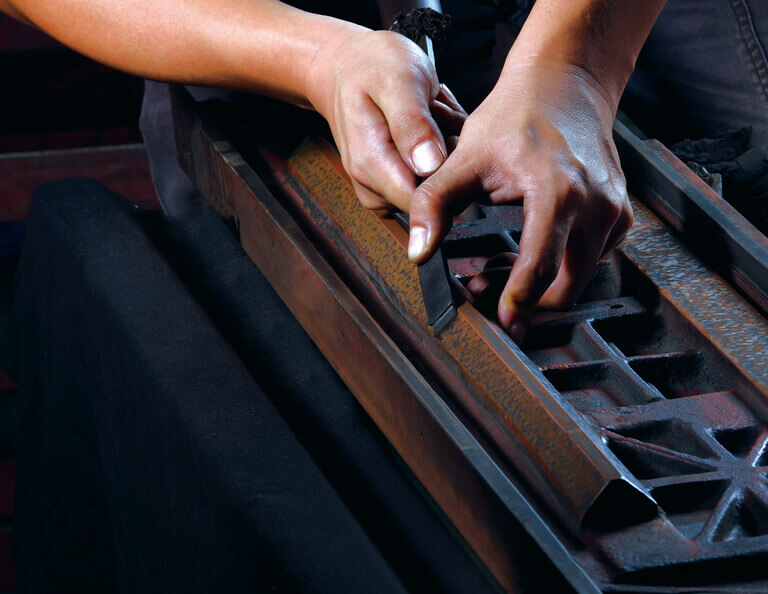

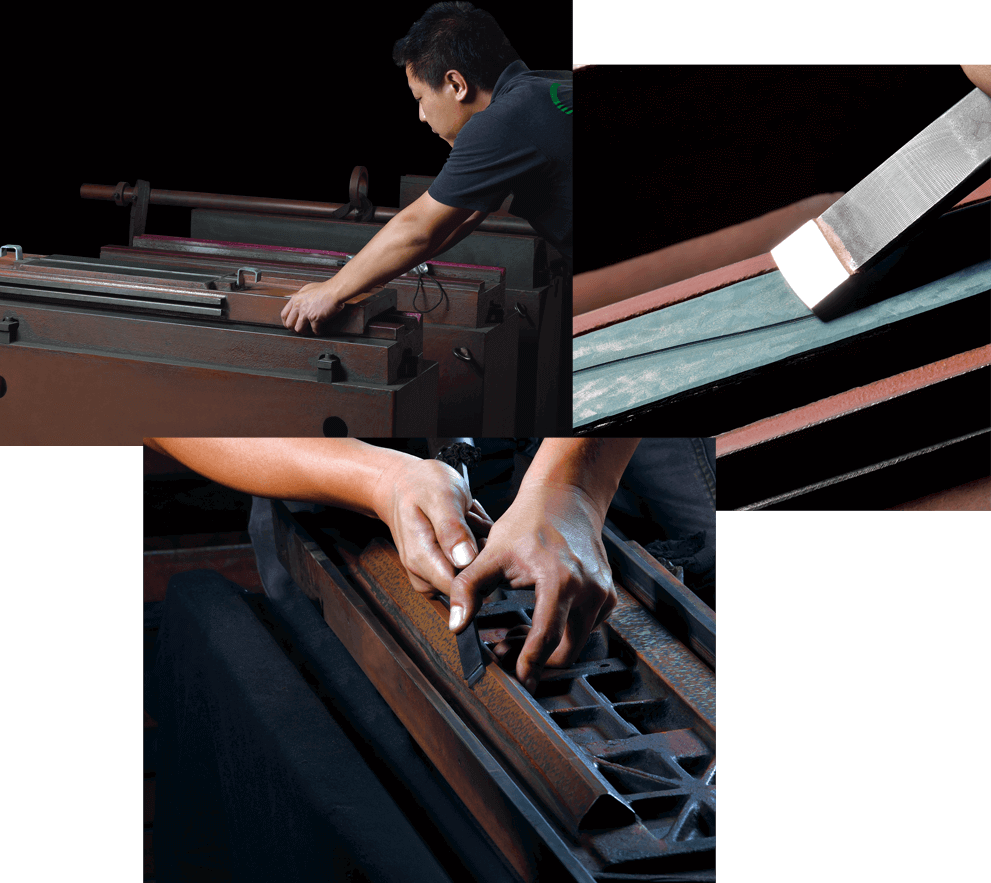

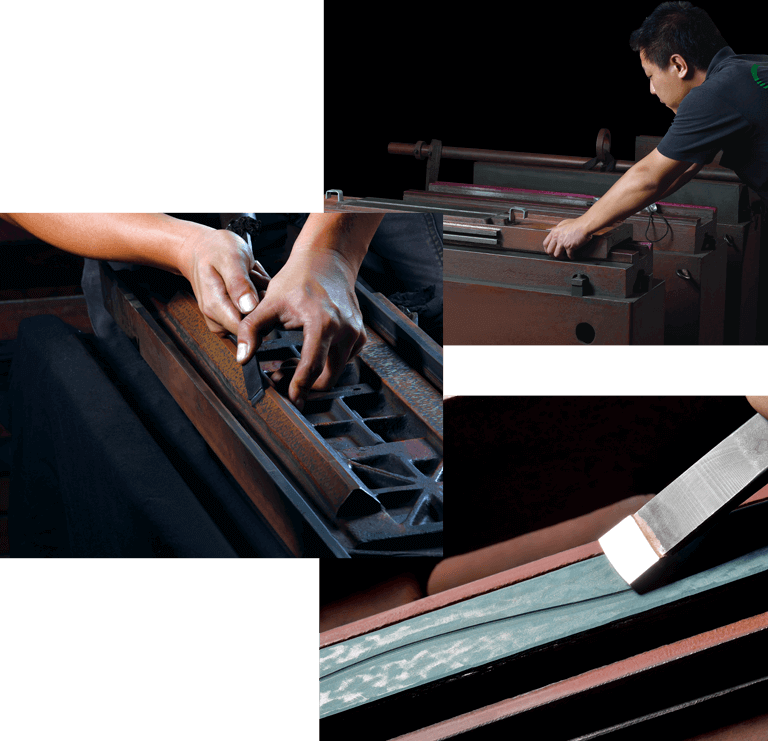

Traditional Hand Scraping

Maintaining Long-term Precision

Using a fixed hand scraper will not only increase the precision of your machine but it will also extend product lifespan.

Spraying the hand scraper two times on both sides before use ensures that the machines sliding suface can be presisely and uniformly scraped. This will give customers the best finish providing high precision machining.

Quality Control

Quality control tests at each stage of the production process reduce the cumulative tolerances during product assembly.

The spindle center is tested around 360 for perpendicularity(with the table support), and a maximum tolerance of 0.003 mm is ensured.

In order to ensure efficient and precise grinding performance all machine gaps are carefully calibrated

Before any machine leaves the factory they are checked for a parallelism and straightness of 0.01mm, which greatly increases the stability during grinding and extends product life.

Customized Design

Innovation and R&D

Through continuous innovation and R&D, our highly skilled personnel can create customized designs to meet customer requirements.

Rigidity & Stability

The main parts of the machine are made from stress relieved Meedhanite castings to ensure rigidity, stability and accuracy

Precision Spindle

The low maintenance precision cartidge spindle is well lubricated and uses NSK P4 high precision bearings ensuring a spindle run out accuracy of 0.002 mm. The sealed and waterproof design also provides excellent durability and machining accuracy.

Optional

The AD models feature Y-axis movement that is controlled by a servo motor and electronic hand wheel wheel whick improves grinding efficiency.

CONTACT US

Request for Support

If you have an enquiry, please contact us using the form. We will respond as quickly and accurately as possible.

Discover